Flow meters for pneumatic conveying

The significance of coal injection is vastly rising in today's steel production business. The aim is to replace as much coke as possible by injecting coal dust into the blast furnace.

Environmental concerns on coke production and the increasing market price for coke accelerate this development.

PCI systems using a static distribution of the injected coal present a technique that keeps down investment costs.

But the deviation among the separate injection lines is rather high and can lead to serious problems within the blast furnace if the deviation remains undetected for longer periods of time.

Only by individual metering and control of each injection line a reliable and long-term stable equal distribution of injected coal can be established.

Cabloc flow meters measure the flow rate of every single injection line fast and precisely

By feeding this measured value into the flow control the deviation can be minimized and the injection rate can be increased.

Application

Cabloc flow meters are used for flow measurement of pneumatically conveyed material, especially in PCI installations at blast furnaces, non-ferrous furnaces and combustion facilities.

Besides coal dust the applied materials are e.g.:

- dusts from filter installations

- ground ores

- pre-reduced intermediate products

- plastics schedule of other applied materials

The flow meters will be delivered pre-adjusted to the different electrical properties of the applied material.

Even the flow of electrically conductive materials can be determined.

Cabloc flow meters are used by customers from various sectors of industry world wide.

Function

The dust concentration present in the transportation line is measured capacitively. The velocity of the particles is determined capacitive-correlatively. From the product of this two measured values, the geometric properties of the conveying line and the material dependent calibration factors the mass flow is calculated.

Multiple logical systems in every Cabloc device carry out the entire processing of the measured values.

The velocity and the pressure of the conveying gas are of no influence to the result of the measurement.

Controlled PCI system with Cabloc flow meters

Calibration and configuration

The flow meters are calibrated and configured by means of a control PC equipped with a CAN-Bus adapter. This way up to 255 Cabloc flow meters in an installation can be administered centrally.

The flow meters are calibrated for equal flow reading from the factory.

If the purpose intended by the user is only to distribute material to several lines equally no additional calibration is needed. If the exact mass flow is to be determined, at least one calibration procedure must be carried out with the material used.

Automatic recalibration that utilizes a signal from a balance as feedback is available as an option. With this option the system will adapt to varying material characteristics automatically.

Output of measured values

- Output of the mass flow and, optionally, material velocity and material concentration via active, ground-free 4 - 20 mA current loops

- Central parameterisation and additional output of measured values via CAN-Bus (twisted pair cable)

- Graphic evaluation of the data with Cabloc / Graph (PC software)

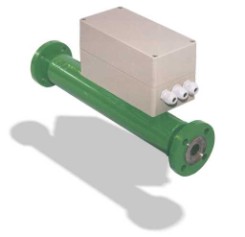

Mechanical construction

Cabloc flow meters are build for heavy duty usage.

A casing made of cast aluminium houses the electronics and protects them against mechanical damage and environmental influences according protection class IP 65.

All electronic circuit boards are located inside the casing mounted on the flow meter.

The units operate stand alone. No additional electronic cabinets or racks are required.

The units comply to the directives 94/9/EG and 97/23/EG for pressure equipment and explosion protection.

Please download our Cabloc product info:

or visit our Download /int. section for further information

PDF (850 kB) problems to view the PDF?